From Sheet to Structure: Best Practices in Tooling & Die Design for Pressed Components

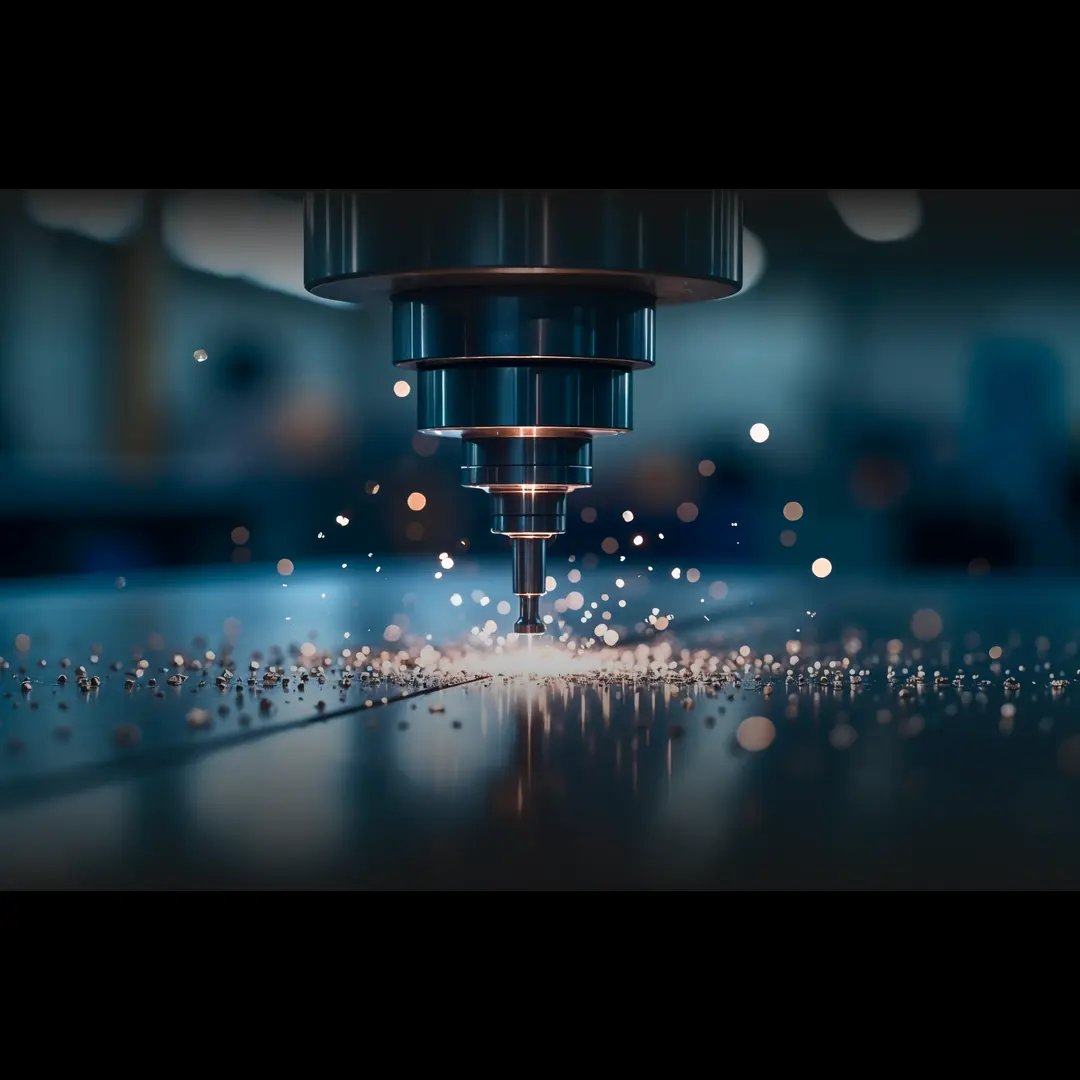

In modern manufacturing, pressed components form the backbone of countless products from automotive body panels and electrical enclosures to intricate industrial assemblies. While the stamping press delivers the muscle, it’s the tooling and die design that define the soul of the operation. A well-engineered die ensures dimensional accuracy, reduces waste, minimizes downtime, and maximizes repeatability across production runs.

Let’s dive into the best practices that convert a flat sheet into a perfectly shaped structure.

1. Start with Material Understanding

Before a single die line is drawn, the material properties must be studied in detail.

Factors like tensile strength, ductility, yield point, and thickness tolerance directly influence the forming behavior. For instance:

Mild steel offers good formability but may suffer from springback.

High-strength low-alloy (HSLA) steel demands higher press forces and precise lubrication.

Aluminum alloys are lightweight but prone to wrinkling and tearing if not handled correctly.

Selecting the right blank size and grain direction can save both material cost and reduce post-forming defects.

2. Emphasize on Die Design Fundamentals

The die is the heart of the stamping process. Whether it’s a simple blanking die or a complex progressive die, every detail counts.

Here are a few essentials:

Die Clearance: Maintain proper clearance (typically 5–10% of material thickness) to ensure clean shearing without excessive burrs.

Punch-Die Alignment: Even minor misalignment can lead to uneven wear and part distortion.

Radii & Fillets: Sharp corners increase stress concentration. Smooth transitions ensure uniform material flow.

Strip Layout Optimization: Smart nesting minimizes scrap and ensures balanced feeding during high-volume runs.

3. Use Simulation for Early Validation

Gone are the days of trial-and-error on the shop floor. Today, CAE and Finite Element Analysis (FEA) tools simulate forming operations to predict wrinkles, thinning, tearing, and springback before the first tool is built.

By testing multiple iterations digitally, designers can adjust draw beads, blank holder pressure, or even material thickness to achieve defect-free results, saving both cost and time.

4. Choose the Right Tool Steel and Surface Treatment

Tool life plays a huge role in consistent quality and cost efficiency. Tool steel selection should balance hardness, toughness, and wear resistance.

Common choices include:

D2 and A2 steels for general stamping

Carbide inserts for long-life precision dies

Powder metallurgy steels for high-strength alloys

Surface treatments like nitriding, PVD coatings, or TiCN further enhance resistance against galling and adhesive wear, especially during dry or high-speed operations.

5. Control Lubrication and Cooling

Pressing generates high friction and heat. Using the correct lubricant formulation ensures smooth material flow and prevents scoring.

In continuous production, integrating cooling channels or thermal control systems within the die body helps maintain dimensional stability and prolongs tool life.

6. Prioritize Maintenance and Die Set Monitoring

Even the best-designed die loses accuracy over time. Routine inspection, polishing, and regrinding schedules keep performance steady.

Modern presses now include real-time load monitoring sensors that detect early signs of wear, misalignment, or overloads, helping avoid costly tool damage.

7. Collaboration Between Design and Production Teams

The most successful stamping projects thrive on cross-functional collaboration. Tool designers, machinists, and press operators must work closely from prototype to production.

Small feedback loops like adjusting die radii, draw bead positions, or blank holder pressures can yield major improvements in part quality and cycle time.

8. Continuous Improvement with Data

Modern stamping lines collect rich data: tonnage, stroke rate, die wear, lubrication levels, and temperature. By analyzing these parameters, manufacturers can refine tooling design, predict maintenance intervals, and push productivity to new levels.

Tooling and die design aren’t just technical tasks, they’re the foundation of efficient, high-quality pressed component manufacturing.

By combining material knowledge, precision engineering, simulation tools, and data-driven optimization, manufacturers can transform a simple sheet of metal into a flawless structure, faster, cleaner, and more profitably than ever before.