**Breaking News: Stay Updated with the Latest in Industrial Innovations & Technology!

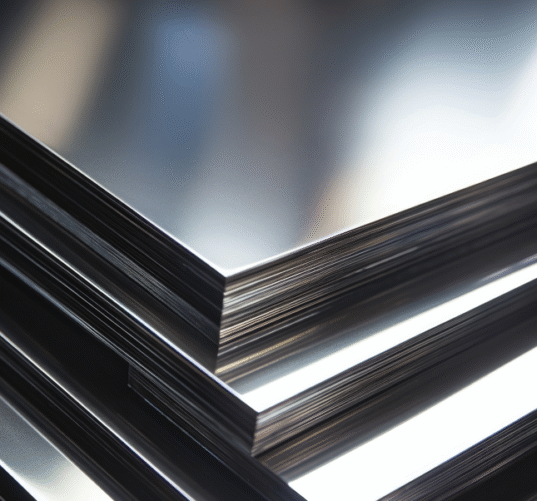

Guide to Choosing the Best Steel Sheets Manufacturer in 2026

In 2026, the demand for high-quality steel sheets continues to rise across industries such as infrastructure, automotive, power, engineering, and heavy manufacturing. With increasing focus on durability, compliance, and supply reliability, selecting the right steel sheets manufacturer is no longer just a procurement decision—it is a strategic one. This guide will help you understand the key factors to consider while choosing the best steel sheets manufacturer in India, ensuring long-term value, performance, and trust. 1. Understand Your Application Requirements Before evaluating manufacturers, it is essential to clearly define your project requirements. Steel sheets are used for a wide range of …

1 month age

The Future of Steel Plate Quality Standards in 2026

In an era of rapid industrial transformation, quality standards in the steel industry are evolving unlike ever before. As a leading steel plate manufacturer in India, Kinetic Industries recognizes the critical importance of maintaining superior product quality while staying ahead of emerging global standards. The year 2026 promises significant advancements that will redefine the way steel plates are produced, measured, and certified. Emerging Trends in Steel Plate Quality Standards The global steel industry is witnessing a shift toward more stringent quality benchmarks driven by technological innovation, sustainability goals, and the demands of modern engineering applications. Key trends that are set …

2 months age

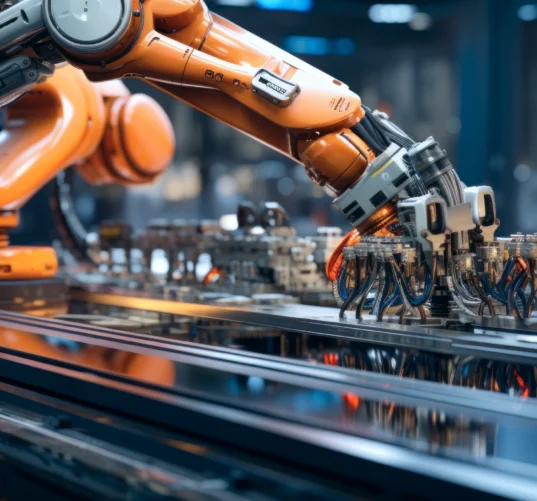

How Indian Stainless Steel Coil Manufacturers Are Evolving in 2026

The Indian stainless steel industry is undergoing a significant transformation in 2026. Driven by global demand, stricter quality standards, sustainability goals, and rapid technological adoption, stainless steel coil manufacturers in India are redefining how they operate, produce, and compete on the world stage. From advanced manufacturing processes to smarter supply chains, this evolution is positioning India as a trusted hub for high-quality stainless steel coils across industries such as infrastructure, automotive, energy, and industrial fabrication. 1. Shift Toward Advanced Manufacturing Technologies One of the biggest changes in 2026 is the widespread adoption of automation and smart manufacturing. Leading stainless steel …

2 months age

Everything You Need to Know Before Buying Refractory Anchors in India

In high-temperature industrial environments, refractory anchors play a critical role in ensuring the structural stability and long-term performance of refractory linings. Whether used in steel plants, cement kilns, power stations, or petrochemical units, selecting the right refractory anchors can significantly impact operational safety, maintenance costs, and furnace life. This guide covers everything industrial buyers, project engineers, and procurement teams in India need to know before purchasing refractory anchors. What Are Refractory Anchors? Refractory anchors are metallic components designed to hold refractory linings securely in place under extreme temperatures, mechanical stress, and chemical exposure. They act as the backbone of monolithic …

2 months age

How to Choose the Right Refractory Anchor Supplier in India

Refractory anchors are a critical component in high-temperature industrial installations. They ensure the structural stability of refractory linings in furnaces, kilns, boilers, reactors, and other thermal equipment. Choosing the right refractory anchor supplier in India is essential for achieving long service life, operational safety, and cost efficiency across industries such as steel, cement, petrochemical, power, and glass manufacturing. This guide outlines the key factors industrial buyers should consider when selecting a reliable refractory anchor manufacturer in India. Understand Your Operating Conditions The first step in choosing the right supplier is understanding your application environment. Refractory anchors must perform under extreme …

2 months age

Supplier Risk Management Strategies for Industrial Buyers in 2026

Global industrial supply chains are facing an era of intensified uncertainty driven by geopolitical shifts, regulatory volatility, technological disruption, and material shortages. As procurement teams prepare for 2026, supplier risk management is no longer a reactive duty but a strategic cornerstone for industrial buyers seeking operational continuity, cost control, and competitive advantage. Strategic supplier management ensures you minimize disruptions, maintain quality standards, and meet delivery commitments across dynamic markets. For industrial buyers, especially those sourcing precision parts and assemblies from trusted partners, working with the best industrial component manufacturer in India strengthens supply chain resilience, enhances quality control, and supports …

2 months age

Quality Certifications That Will Matter Most in Industrial Manufacturing in 2026

In an era where manufacturing excellence defines competitive advantage, quality certifications have become essential benchmarks that separate industry leaders from the rest. For companies striving to position themselves as the best industrial component manufacturer in India, acquiring and maintaining globally recognized certifications not only boosts credibility but also enhances operational efficiency, customer confidence, and access to international markets. At Kinetic Industries, quality is foundational to every process. As a precision-engineered industrial and engineering components provider, Kinetic Industries has built its reputation on stringent quality policies and adherence to internationally accepted standards that drive consistency, reliability, and excellence in manufacturing. 1. …

2 months age

Choosing the Right Precision Manufacturing Partner for 2026 and Beyond

In 2026, industrial companies are facing greater pressure than ever to deliver higher performance, better quality, and more efficient production cycles. Whether you’re in automotive, aerospace, power, construction, or petrochemical sectors, choosing the right manufacturing partner can make the difference between meeting your goals and falling behind. For businesses seeking the best industrial component manufacturer in India, understanding what to look for in a partner is critical to long-term success. What Precision Manufacturing Means for Your Business Precision manufacturing isn’t just about making parts. It’s about delivering components that fit exactly, perform reliably under stress, and integrate smoothly into complex …

3 months age

Industrial Components for Refractories in India: Powering High-Temperature Industries

In the heart of India’s industrial growth lies a critical yet often understated sector: the refractory industry. Refractories are advanced materials capable of withstanding extremely high temperatures, corrosive environments, and physical wear. These materials form the backbone of high-temperature industrial processes — from steelmaking in blast furnaces to cement kilns, glass furnaces, and more. As Kinetic Industries, specializing in industrial components, understanding the refractory landscape in India is not just strategic — it’s foundational. In this post, we’ll explore the key components used in refractories, their role in India’s industrial ecosystem, and how leading companies like yours can add value …

3 months age

How to Choose the Right Pressed Components Manufacturer in India

When it comes to modern manufacturing, pressed components play a crucial role in industries such as automotive, electrical, construction, and heavy engineering. These precision-engineered metal parts form the backbone of countless applications — but the quality of the final product depends heavily on the manufacturer you choose. If you’re looking for a reliable pressed components manufacturer in India, here’s a comprehensive guide to help you make the right decision. 1. Evaluate Manufacturing Capabilities Before partnering with a manufacturer, assess their production capabilities. Check whether they have advanced press machines, tooling facilities, and automation technologies that can handle the volume, complexity, …

4 months age

Selecting the Right Refractory & Insulation Accessories for High-Temperature Industrial Furnaces

In any high-temperature industrial setup — whether it’s a steel furnace, rotary kiln, or petrochemical heater — the reliability of the system depends heavily on the refractory and insulation materials used. However, one element that often gets overlooked is the refractory and insulation accessories. These accessories play a crucial role in supporting, securing, and maintaining the performance of the lining system under extreme conditions. At Kinetic Industries, we supply a comprehensive range of refractory and insulation accessories engineered for durability and high-temperature performance. Let’s look at how you can select the right ones for your application. 1. The Importance of …

4 months age

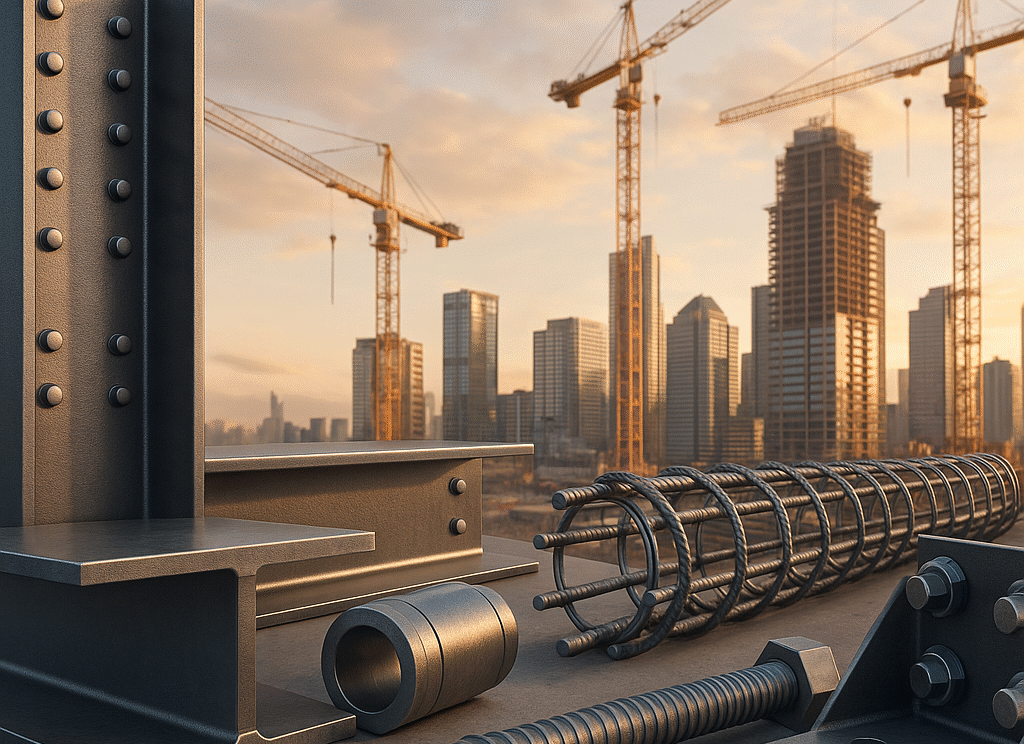

Future Trends: Steel Products for Renewable Energy Infrastructure (Wind Towers, Solar Frames, etc.)

In the global push toward low-carbon energy, the infrastructure of renewable power is rapidly scaling up. Whether it’s on-shore or off-shore wind farms, large solar parks, or hybrid renewable + storage systems, steel is one of the critical materials that makes this scale-up possible. This blog explores what steel products are needed, what properties they must have, which standards govern them and what cost-pressures and trends are shaping the market. 1. Steel Products Needed for Renewable Energy Infrastructure When you look at a wind farm or solar park, the visible “green” equipment (turbines, blades, panels) gets most of the attention—but …

4 months age

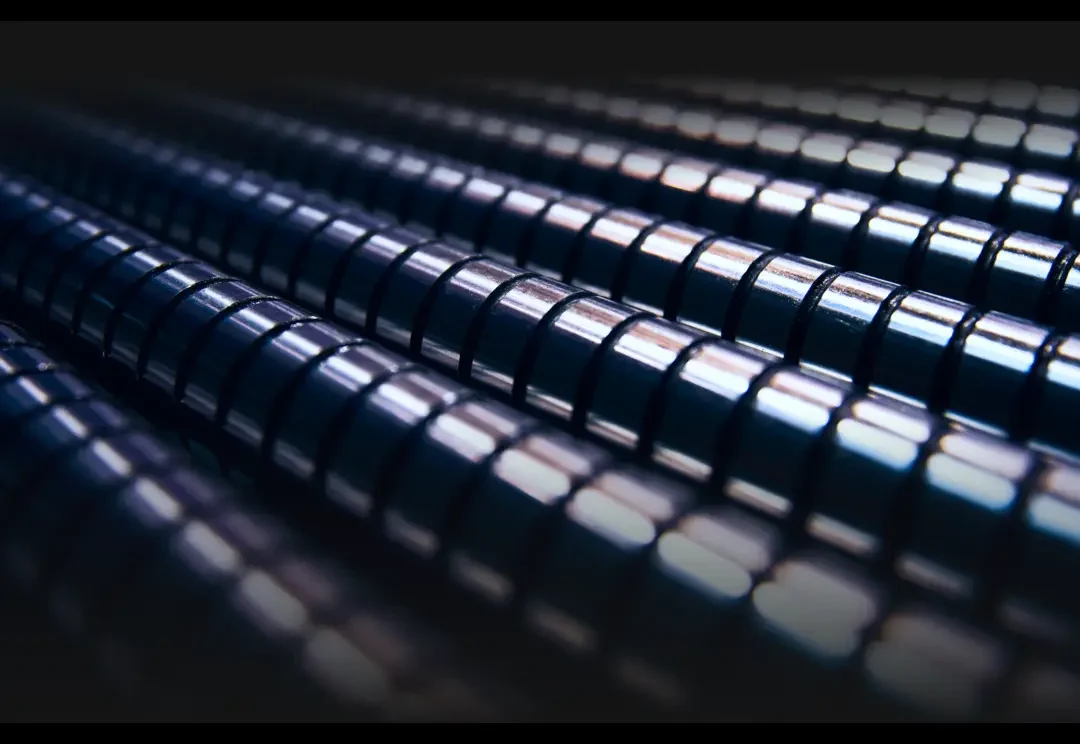

A Complete Guide to Different Steel Grades: Properties, Advantages & Uses

Steel is one of the most versatile and widely used materials in modern industry. From construction to automotive, and from household appliances to heavy machinery — steel plays a crucial role in shaping our world. However, not all steels are the same. Understanding the different steel grades helps in selecting the right material for specific applications. In this guide, we’ll compare the four major types of steel — Mild Steel, Carbon Steel, Alloy Steel, and Stainless Steel — and explore their unique properties, advantages, and uses. 1. Mild Steel Overview Mild steel, also known as low-carbon steel, contains a relatively …

4 months age

From Sheet to Structure: Best Practices in Tooling & Die Design for Pressed Components

In modern manufacturing, pressed components form the backbone of countless products from automotive body panels and electrical enclosures to intricate industrial assemblies. While the stamping press delivers the muscle, it’s the tooling and die design that define the soul of the operation. A well-engineered die ensures dimensional accuracy, reduces waste, minimizes downtime, and maximizes repeatability across production runs. Let’s dive into the best practices that convert a flat sheet into a perfectly shaped structure. 1. Start with Material Understanding Before a single die line is drawn, the material properties must be studied in detail. Factors like tensile strength, ductility, yield …

4 months age