How Smart Automation is Changing Industrial Manufacturing

AI and Robotics: The Core of Smart Manufacturing

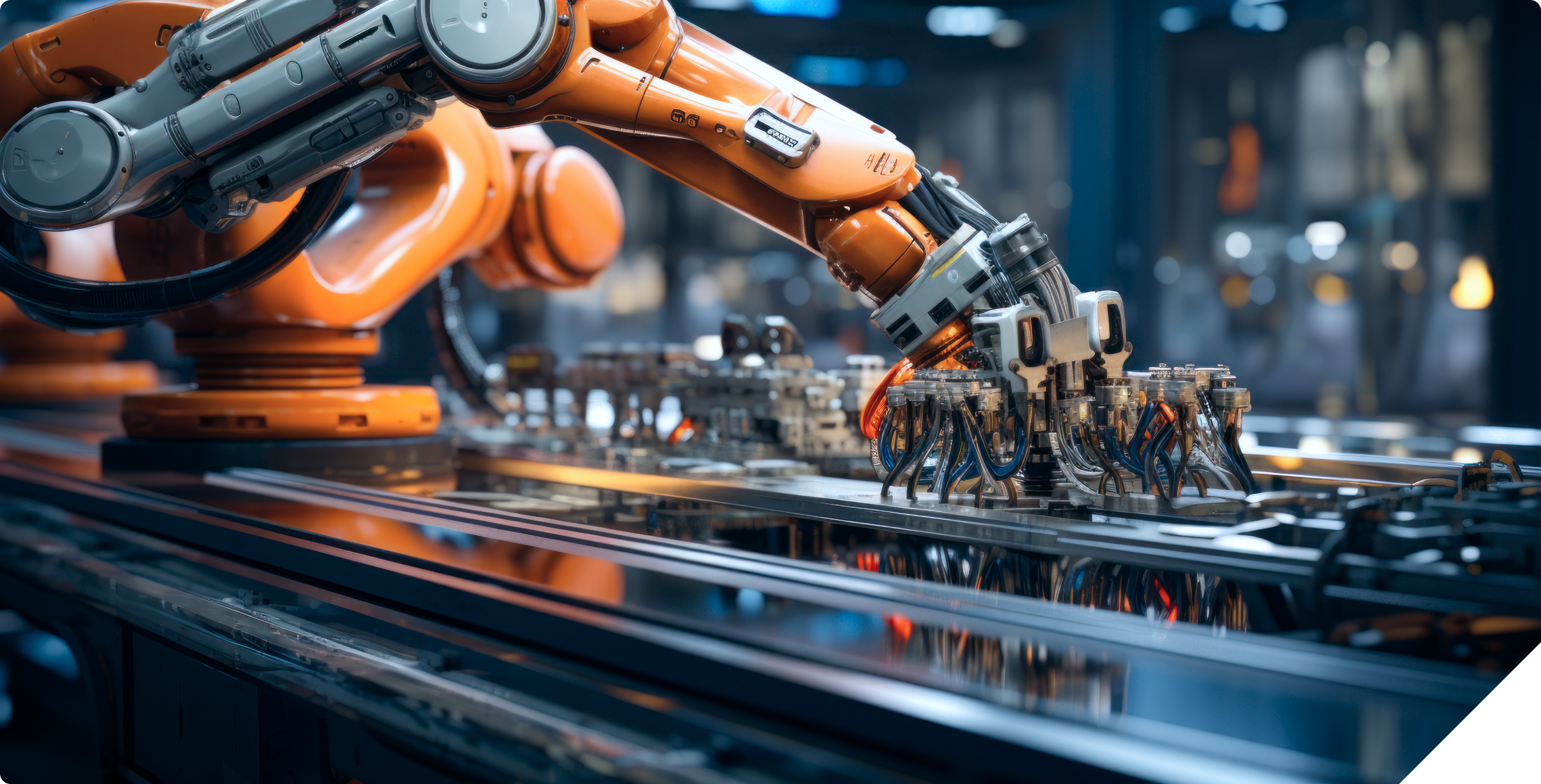

At the heart of smart automation lies the synergy between artificial intelligence and robotics. AI-driven machines are no longer just executing pre-programmed tasks; they are learning, analyzing, and making autonomous decisions to improve productivity. Collaborative robots, also known as “cobots,” are working alongside human operators to enhance efficiency and precision in manufacturing processes.

Robotic automation is being implemented across industries for tasks such as assembly, welding, packaging, and material handling. These intelligent machines are equipped with sensors and computer vision technology, allowing them to adapt to variations in components, detect defects in real time, and adjust their operations accordingly. Unlike traditional automation, which relies on fixed programming, AI-powered robots can continuously optimize their performance, leading to reduced errors and improved product quality.

Furthermore, AI-driven predictive maintenance is changing the way industries manage equipment. By analyzing data from sensors embedded in machinery, AI can predict potential failures before they occur, allowing manufacturers to schedule maintenance proactively. This approach minimizes downtime, extends machine life, and prevents costly disruptions in production.

IoT-Enabled Smart Factories: The Future of Manufacturing

The Industrial Internet of Things (IIoT) is another driving force behind smart automation, connecting machines, systems, and people within a manufacturing environment. Smart factories equipped with IoT sensors continuously collect and analyze data, enabling real-time monitoring, predictive analytics, and seamless communication between production units.

One of the most significant benefits of IoT in manufacturing is enhanced supply chain visibility. Smart sensors track the movement of raw materials, monitor inventory levels, and optimize logistics operations, ensuring that production runs smoothly without bottlenecks. This real-time data sharing between suppliers, manufacturers, and distributors enhances efficiency and responsiveness to market demands.

Additionally, IoT-driven automation reduces waste and energy consumption. Smart manufacturing systems can detect inefficiencies in energy use, adjust machine settings to minimize waste, and implement energy-saving protocols. This not only lowers operational costs but also contributes to sustainability efforts by reducing the carbon footprint of manufacturing plants

Machine Learning and Data Analytics: Driving Intelligent Decision-Making

Machine learning and data analytics play a crucial role in smart automation by enabling predictive insights and process optimization. Unlike traditional automation systems that follow predefined instructions, machine learning algorithms analyze vast amounts of data to identify patterns, optimize workflows, and predict future trends.

For example, in quality control, AI-powered image recognition systems can detect even the slightest defects in products with unmatched accuracy. This eliminates the need for manual inspections and ensures that only flawless products reach the market. Additionally, smart algorithms can analyze customer preferences and production trends, allowing manufacturers to anticipate demand fluctuations and adjust their operations accordingly.

In supply chain management, machine learning enhances demand forecasting by analyzing historical sales data, market conditions, and external factors such as weather patterns and economic trends. This enables manufacturers to optimize inventory levels, reduce overproduction, and minimize storage costs, resulting in a leaner and more cost-effective supply chain.

The Human-Machine Collaboration: Enhancing Workforce Efficiency

One of the most significant misconceptions about automation is that it will replace human workers. However, smart automation is not about eliminating jobs but rather augmenting human capabilities. By automating repetitive and physically demanding tasks, workers can focus on higher-value activities such as innovation, problem-solving, and process optimization.

Cobots, designed to work safely alongside human operators, are improving productivity in manufacturing plants. Unlike traditional industrial robots that require extensive safety measures, cobots are equipped with sensors that allow them to detect human presence and adjust their actions accordingly. This makes them ideal for precision tasks that require both human dexterity and robotic accuracy.

Moreover, smart automation is creating new job opportunities in fields such as AI programming, data analysis, and robotics maintenance. As industries transition towards automated systems, the demand for skilled professionals who can manage, troubleshoot, and optimize these technologies is increasing.

Conclusion: The Future of Smart Automation in Industrial Manufacturing

Smart automation is no longer a futuristic concept—it is a present-day reality transforming industrial manufacturing across the globe. By leveraging AI, robotics, IoT, and machine learning, manufacturers are achieving higher efficiency, improved product quality, and cost savings that were once unimaginable.

As smart factories become the standard, industries that embrace automation will gain a competitive edge in an increasingly digital and fast-paced market. The integration of intelligent systems will enable manufacturers to adapt to evolving customer demands, enhance supply chain resilience, and drive innovation at an unprecedented scale.

Ultimately, the future of manufacturing lies in a balanced partnership between humans and machines. As technology continues to evolve, industries must invest in upskilling their workforce, embracing digital transformation, and harnessing the full potential of smart automation. By doing so, they will not only improve operational efficiency but also shape the future of industrial manufacturing for generations to come.