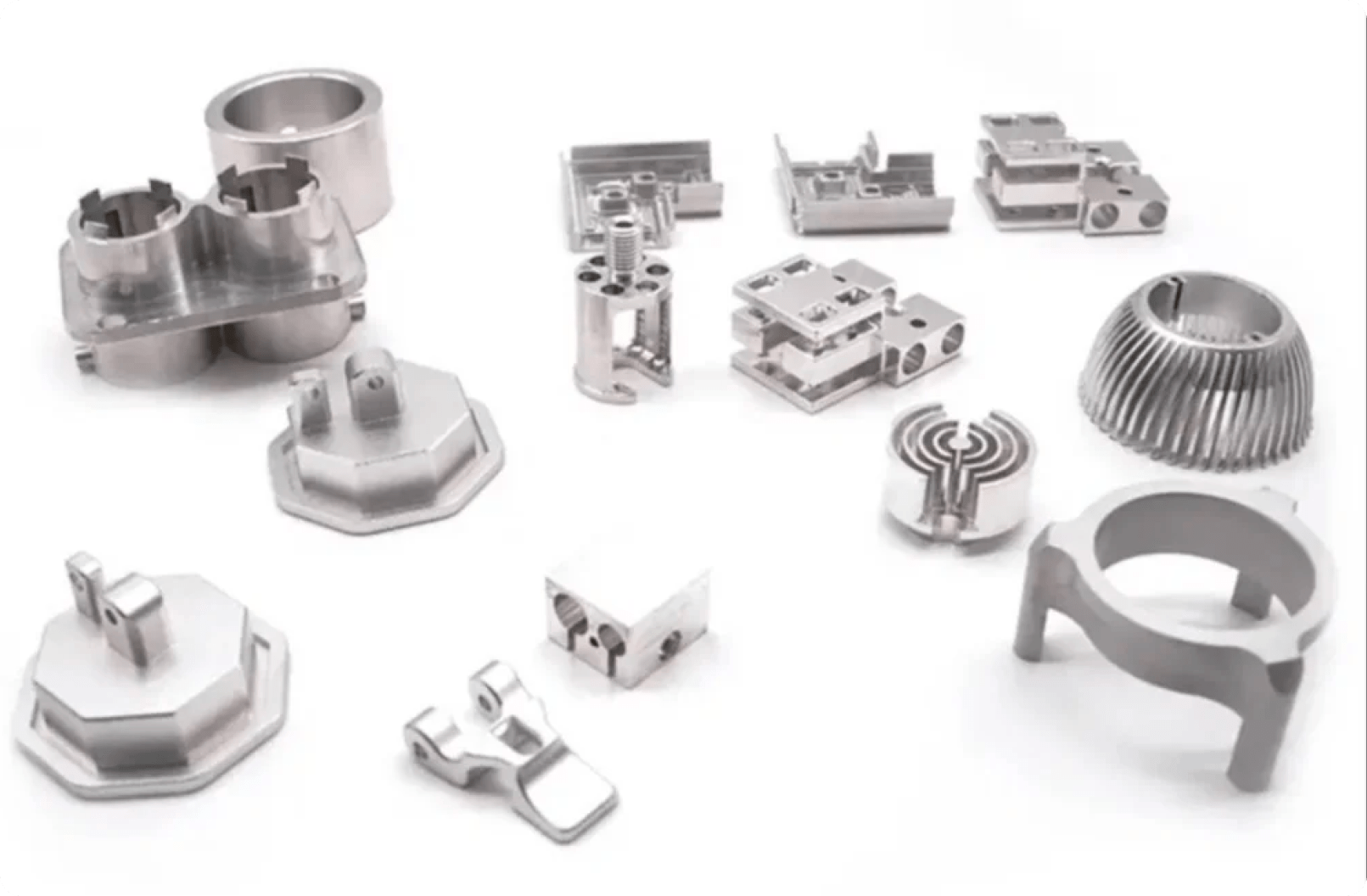

Designed for strength, accuracy, and durability, our industrial components are engineered to excel in critical applications. Utilizing cutting-edge manufacturing techniques and premium materials, we ensure optimal performance, seamless integration, and long-term reliability across diverse industries.

Built for precision and durability,

our Pressed components

ensure seamless performance,

reliability, and efficiency in every

application.

500+

Custom Engineering Solutions delivered across industries.

20+

High-grade materials used for superior strength and durability.

1,00,000+

Components manufactured annually, ensuring large-scale production capabilities.

Performance Backed

by Numbers

Precision-engineered to deliver unmatched reliability, our industrial components stand strong with proven performance metrics. These numbers reflect our dedication to quality, innovation, and customer trust.

01

Pressed & Turned

Metallic Components

In today’s fast-evolving manufacturing landscape, Pressed Components and Turned Metallic Components are essential to precision-driven industries like automotive, aerospace, and infrastructure. These metallic components are engineered to deliver high strength, accuracy, and cost-efficiency—making them ideal for everything from engine assemblies to structural supports. As demand grows for smart, scalable engineering components, top Pressed Component Manufacturers and Pressed Component Suppliers are stepping up with advanced fabrication technologies and materials. At the heart of modern industrial components, these precision-formed parts are not just functional—they’re foundational. Whether for machines or construction materials, pressed components define durability in a rapidly changing industrial era.

02

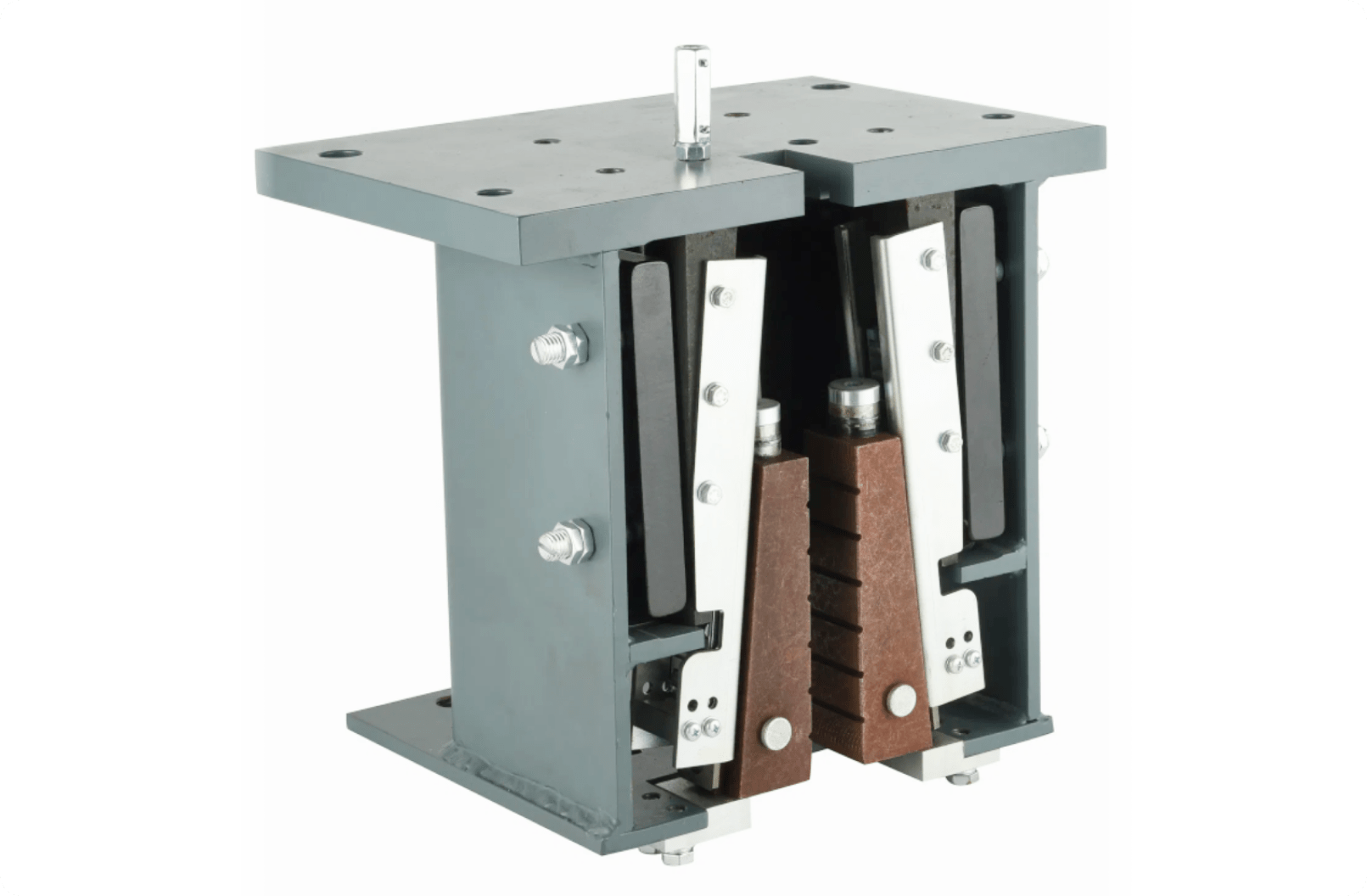

Elevator/

Lift Components

As modern Architecture reaches new heights, Elevator Components play a crucial role in ensuring safety, efficiency, and smooth vertical transportation. As buildings grow taller and smarter, the demand for reliable Elevator parts manufacturers has been higher. From control panels to guide rails and safety gears, each component contributes to performance and compliance. A leading Elevator Components manufacturer and Elevator Components supplier offers high-precision lift components built for longevity and low maintenance. With the rise of smart cities and automation, even Escalator components are evolving to integrate IoT and energy efficiency—making modern elevators not just transport tools, but intelligent systems.

03

Mild

Fabricated Products

In today’s era of precision manufacturing and sustainable engineering, Mild fabricated solutions are becoming essential across industries. From automotive to construction, Fabricated pressed components deliver strength, reliability, and custom design adaptability. Each Fabricated component is engineered to meet tight tolerances and evolving performance standards, making them indispensable in today’s high-demand sectors. Whether it’s lightweight frames or robust support structures, Metal pressed components offer superior structural integrity while keeping costs in check. As demand grows for smarter and more efficient systems, Fabricated products—especially Mild fabricated assemblies—are redefining durability and design flexibility in modern fabrication practices.

04

Custom

Engineering Solutions

In a world driven by precision and innovation, Custom engineering solutions are at the core of modern manufacturing. Businesses across sectors now demand tailored parts that meet unique operational requirements—this is where Custom component manufacturing takes the lead. From high-performance Threaded Fittings & Connectors to precision-machined Bushes, Sleeves & Collars, and robust Screw shafts, every part is designed to deliver optimized functionality and reliability. With industries moving towards smart automation and lean production, Custom Engineering solutions ensure perfect integration, enhanced durability, and minimized downtime. These advanced Custom components are not just products—they’re engineered answers to tomorrow’s challenges.

05

High-Quality

Materials

Crafted for the future, our products are engineered using premium stainless steel material, the Gold standard for Durability, Performance, and Resistance. From Precision shafts and Axles to Ball joints, Splined bush, and Flanged mounting rings, every component is designed to withstand extreme conditions while delivering unmatched reliability. With stainless steel at the core, we ensure strength without compromise, offering superior resistance to corrosion and wear. Our advanced manufacturing techniques fuse innovation with strength, making these products the backbone of high-performance machinery. Choose excellence. Choose longevity. Choose the power of Stainless steel material in every precision-engineered part we create.

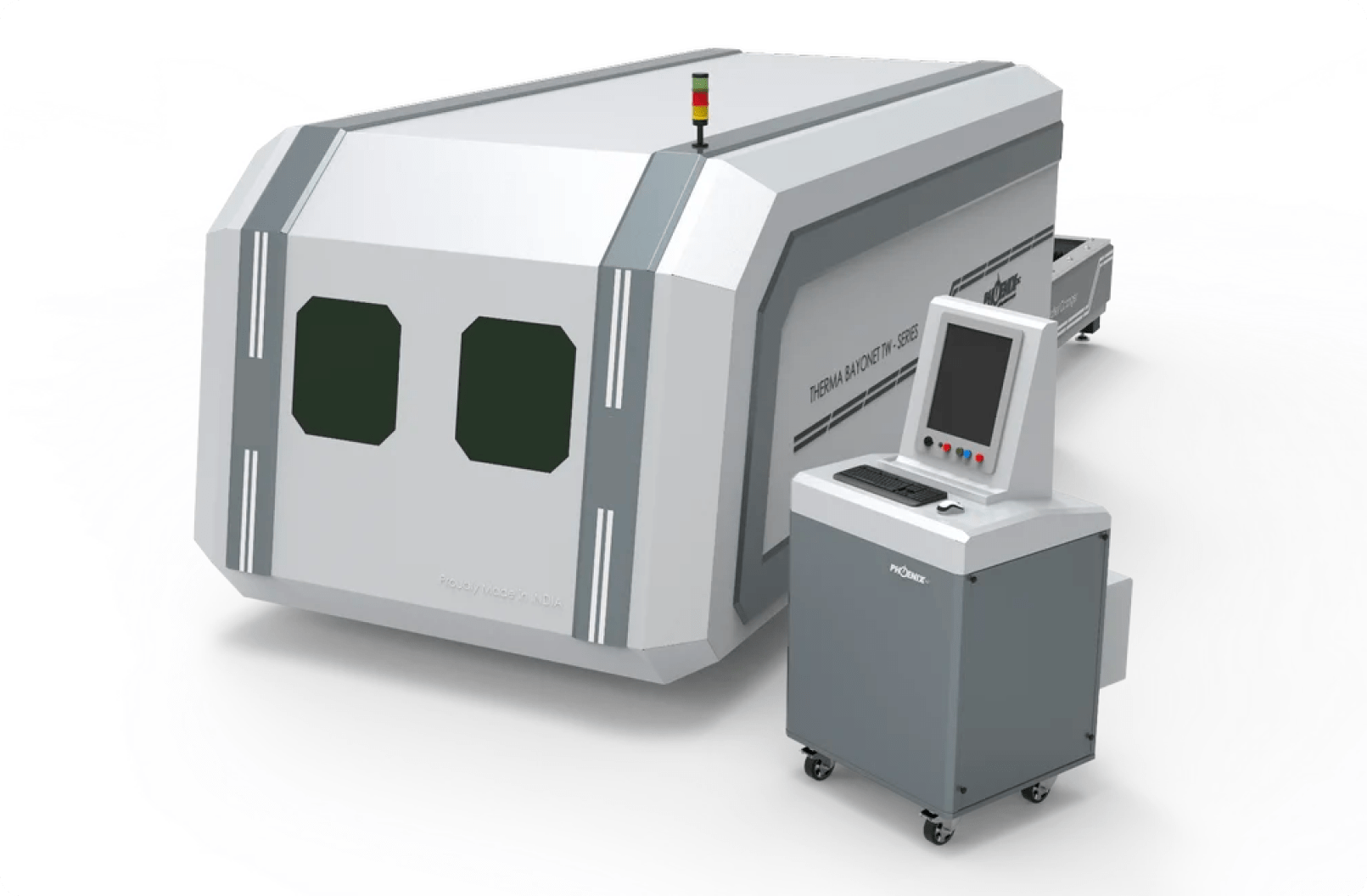

06

Precision

Manufacturing Processes

Welcome to the future of Precision Manufacturing, where innovation meets accuracy. Our state-of-the-art facility specializes in CNC machining, laser cutting, and Stamping to craft high-performance components with unmatched precision. As a trusted CNC metal parts manufacturer, we harness the power of advanced CNC milling machines and cutting-edge laser cutting services to deliver intricate designs and flawless finishes. Every part we produce reflects our mastery in Precision engineering components, built to meet the most demanding industrial standards. Whether prototyping or scaling, we redefine what’s possible—where speed, strength, and sophistication converge. Precision isn’t a promise—it’s our process.

Designed for Precision and Reliability.

Our high-quality components offer superior

performance, durability, and efficiency to support

seamless industrial operations.

Call us at -

7999629007

Mail us at -

jmb@kineticindustries.in info@kineticindustries.in

Meet us at -

No5, Adham Tannery Street,

Nagalkeni Chromepet, Chennai, Tamilnadu 600044,

India.

FAQs

Answer: A Pressed Component is a component created through the action of pressing high-force pressure against sheet metal, which is molded into the desired shape by dies and presses. It is also referred to as metal stamping or pressing and enables mass production of precision components with uniform quality and dimensions. Top Pressed Component producers such as Kinetic Industries employ mechanical or hydraulic presses along with sophisticated CAD/CAM tools to produce intricate shapes efficiently. Such components are widely utilized in sectors such as automotive, aerospace, and elevator manufacturing, where lightness, precision, and strength are essential. Our efficient production processes provide maximum cost-effectiveness along with high-speed output.

Answer: Pressed parts play a crucial role in sectors requiring durability, consistency, and inexpensive mass production. These are the automobile, aerospace, elevator/lift, electrical, and consumer appliance sectors. As professional Pressed Component Suppliers, Kinetic Industries has expertise in supplying to the automotive sector with suspension and transmission components, the aerospace sector with accurate cabin and structural parts, and the elevator sector with safety-critical components and elevator accessories. From lift components suppliers to elevator spare parts manufacturers, our capabilities extend across high-demand and safety-critical applications. The versatility of pressed components renders them an absolute necessity for applications in modern engineering.

Answer : Kinetic Industries provides a broad range of pressed components for mission-critical applications in various industries. Our product portfolio consists of brackets, bushings, plates, flanges, support frames, and tailored components for application in automotive, aerospace, and elevator systems. Being a leading Pressed Components Automotive Maker and Aerospace Component Distributor, we supply products for performance, durability, and longevity. In elevator-specific products, we provide components for doors, cabins, safety gears, and many more, positioning ourselves as a reliable Elevator Components Manufacturer and Elevator Spare Parts Distributor. Every part is designed to match certain industry standards and customer demands with great accuracy.

Answer : Pressed parts usually are produced from a range of metals depending on the performance requirements of the application. Mild steel, stainless steel, aluminum, copper, and other hard alloys are some of the common materials. As a seasoned steel and stainless steel component supplier, Kinetic Industries selects materials based on strength, corrosion resistance, weight, and cost-efficiency. For aerospace components, lightweight alloys and corrosion-resistant materials are prioritized, while elevator parts manufacturers often use stainless steel for durability and aesthetic appeal. Our in-house material selection process ensures that every product meets industry-specific performance standards while remaining cost-effective.

Answer : Kinetic Industries is unique among Pressed Component Manufacturers because of our unrelenting dedication to quality, accuracy, and customer satisfaction. We blend sophisticated manufacturing technology with experienced engineering to provide superior-performance pressed components specifically designed for your industry—automotive, aerospace, or elevators. As top-rated Elevator Components Suppliers and Aerospace Component Manufacturers, we follow global quality standards and make sure each part is thoroughly tested. Our large-scale production capabilities, special design assistance, and timely delivery schedules make us the first choice Pressed Component Supplier in India. Relieve yourself of the uncertainty with Kinetic Industries for reliability, innovation, and engineering prowess you can rely upon.